Doctoral Candidate | Mining Engineering

Imperial College London (United Kingdom)

Advisor: Sevket Durucan

Itasca Mentor: Ehsan Ghazvinian

Introduction

The objective of this research is to understand the mechanism of rock burst and gas outburst occurrences in deep underground coal mines. Rock and coal samples were sourced from a few field study sites, such as the Velenje coal mine in Slovenia and the Pniowek coal mine in Poland. The samples were then analyzed and measured for elastic, mechanical, and reservoir properties to provide input for numerical modelling analyses in the geomechanics and rock physics laboratory at Imperial College London. Additionally, the strain energy accumulation in a retreating longwall mining panel was evaluated using an analytical equation.

Numerical Modelling – Using FLAC3D to Validate the Developed Analytical Equations

Analytical equations were developed to estimate the elastic strain energy accumulated at the active face of a retaining longwall mining panel, where the most dominant parameters were identified to be mining depth, length of the cantilever goaf, coal seam thickness, roof thickness, and Young’s modulus of the coal and roof. By developing a mine-scale numerical model in FLAC3D, the developed analytical equations with similar trends for corresponding mining scenarios were validated.

Mine-Scale Numerical Models

The elastic, mechanical, and reservoir properties determined in the laboratory were used to simulate several mine-scale numerical models, where two approaches were used to optimize the mining layout:

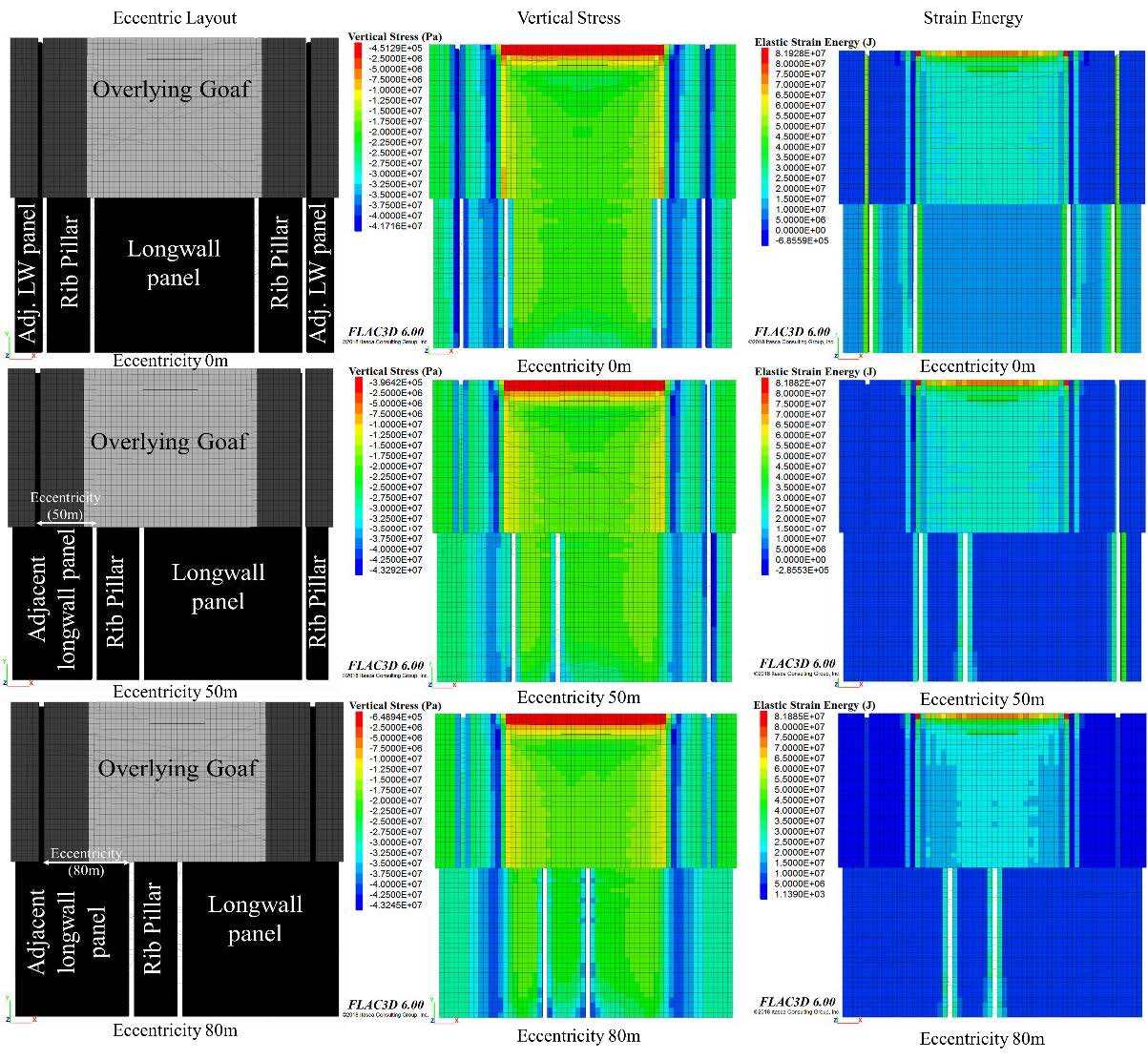

- Stress-controlled mining methods (Figure 1).

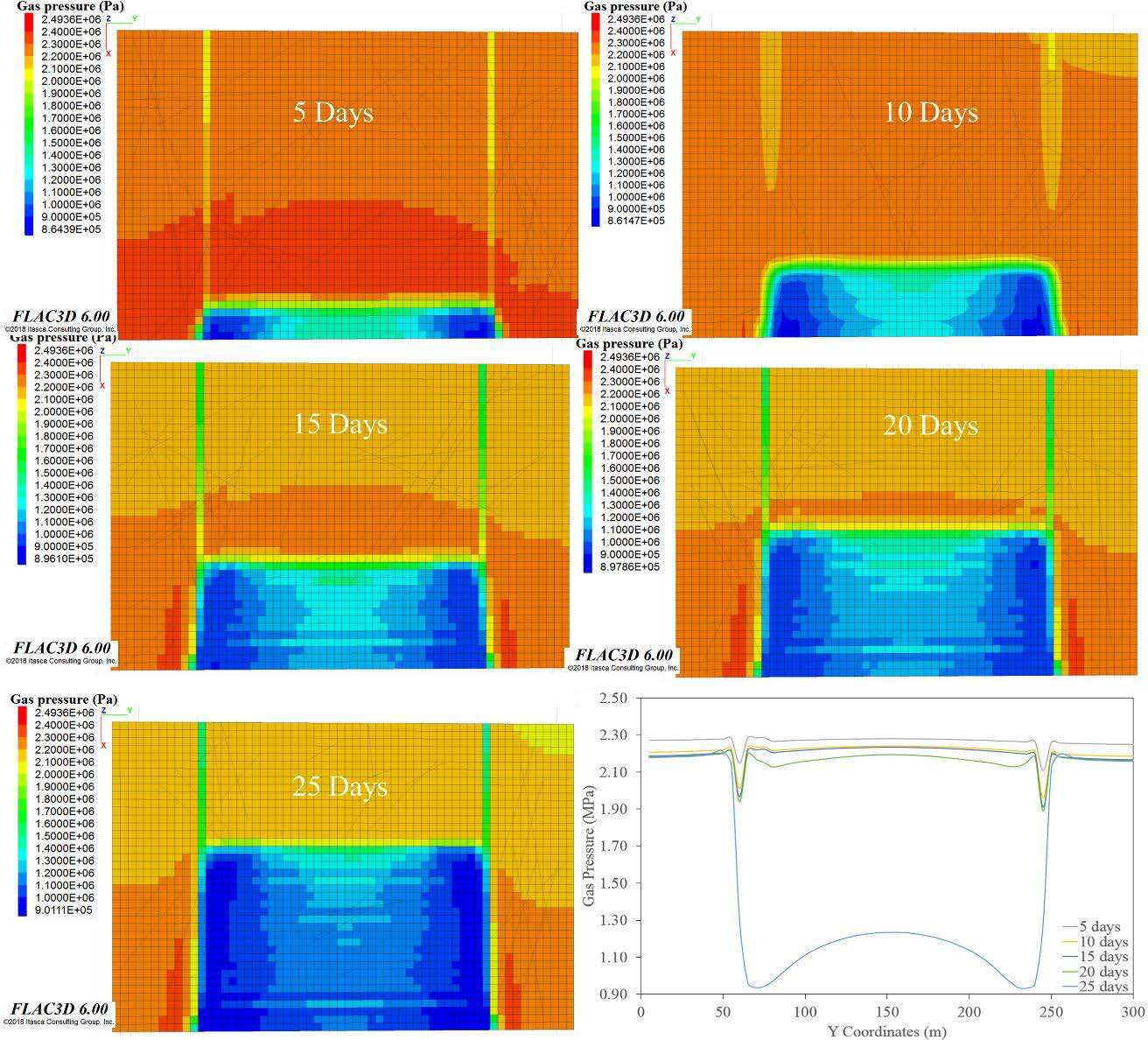

- Gas-pressure-controlled mining methods (Figure 2).

For the stress-controlled mining methods, several mining scenarios were designed by varying pillar and panel geometry, eccentric mining layouts (Figure 1), and sacrificial roadways. From the analysis, it was observed that symmetrical mining layouts accumulated lesser vertical stress and strain energy. In the case of multi-seam workings, lateral shifting of the roadways by half of the longwall panel width minimized the vertical stress and strain energy accumulation in the lower seams.

In the case of the gas pressure-controlled mining method, a coupled numerical model was developed between FLAC3D from Itasca and ECLIPSE from Schlumberger to facilitate a seamless exchange of permeability at every excavation step using a MATLAB routine. A parametric analysis was conducted to analyze the influence of a protective seam in reducing the risk of rock bursts and gas outbursts in the protected (gassy) seam (Figure 2). It was also found that the presence of a protective seam (within approximately 20 m above the protected seam) has a strong influence on reducing the risk of rock bursts and gas outbursts in the protected seam. The influence decreases with an increase in the inter-bedding thickness, where the inter-bedding thickness as well as the nature of the rock in the inter-bedding layers are vital for the success of the protective mining technique.

Modeling the Lithological Heterogeneity with FLAC3D

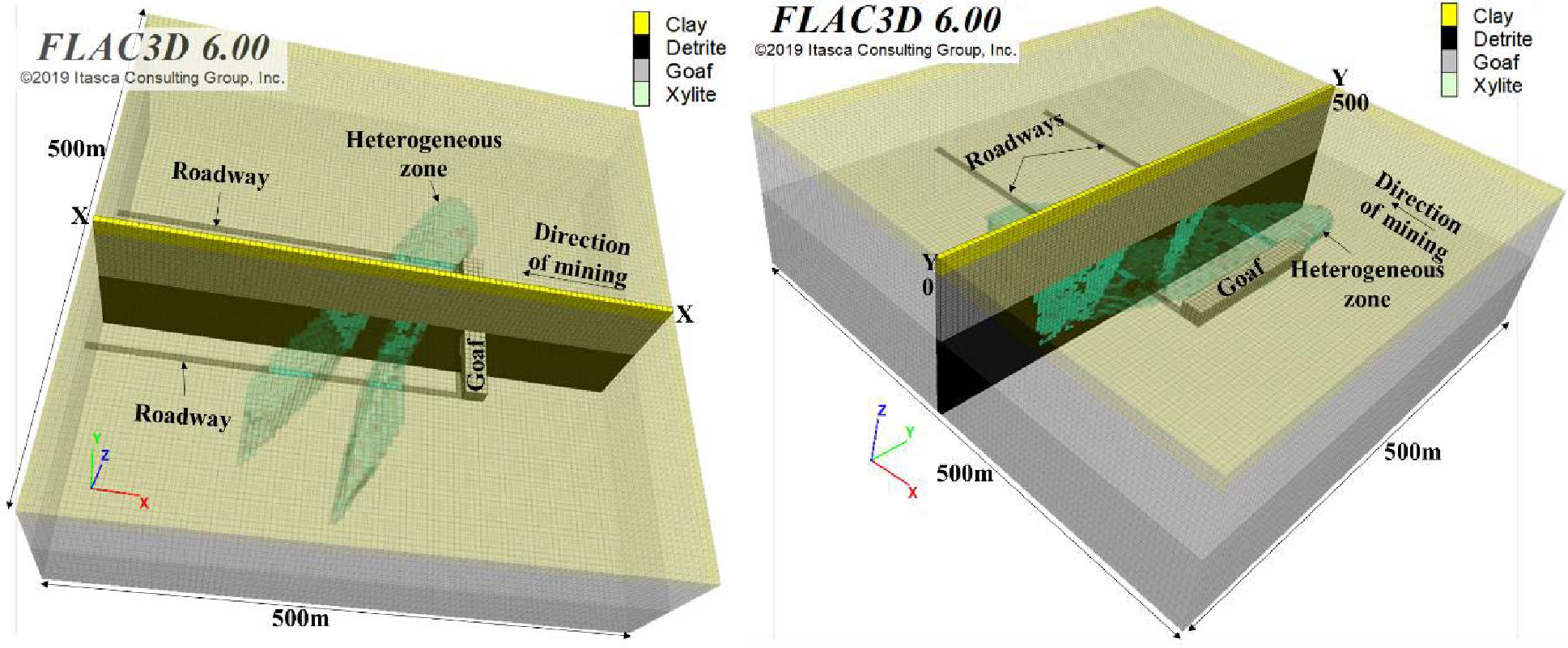

To model the influence of lithological heterogeneity, a fork-shaped solid was placed in the mined seam as the heterogeneous zone (Figure 3). The lithology in the heterogeneous zone was distributed using a geostatistical, object-based, non-conditional simulation approach to represent different geospatial mining scenarios at the Velenje coal mine.

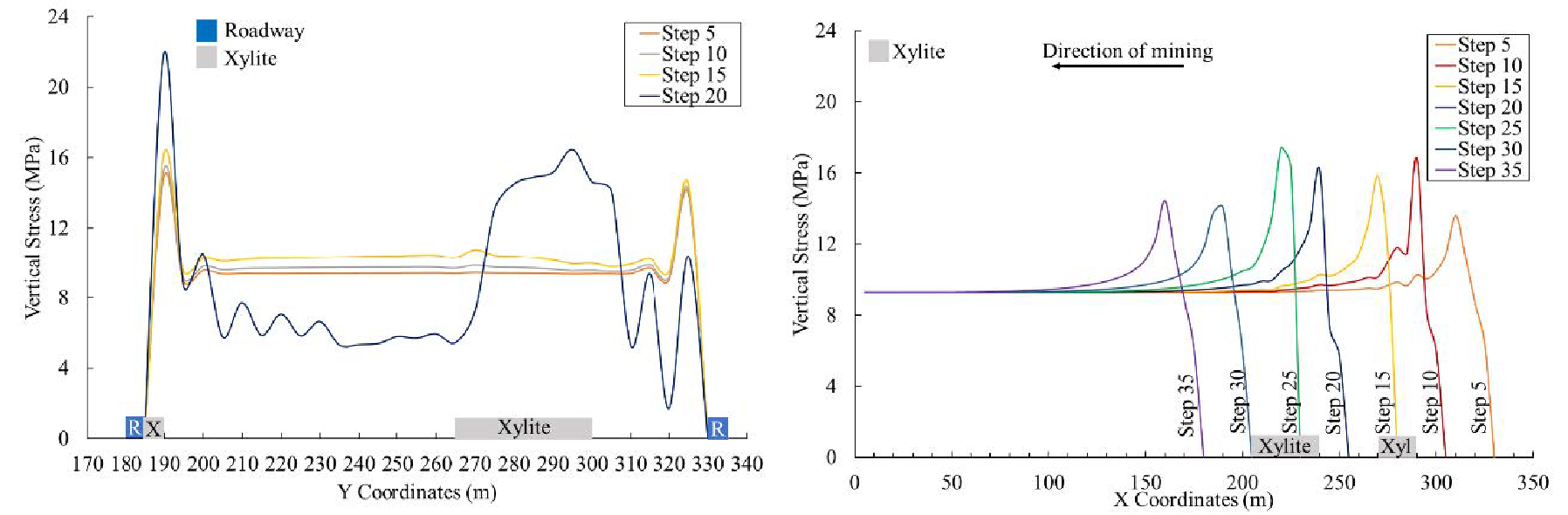

Several sub-routines were written in FLAC3D to incorporate the lithological heterogeneity in the coupled numerical model. In a preliminary analysis of the heterogeneity variation along cross-sections XX and YY (Figure 3), it was found that the heterogeneity strongly influences the redistribution of vertical stress (Figure 4), pore pressure, strain energy, and gas flow rate.

The vertical stress, pore pressure, strain energy, and the gas emission rate obtained from the coupled numerical model were fed into a probabilistic risk assessment framework developed in this research to calculate the probability of rock burst and gas outburst occurrences. The dynamic nature of retreating mining was properly captured by providing feedback from the updated modelling state into the framework. The stochasticity in the parameters was also incorporated and propagated throughout the framework using the Monte Carlo simulation approach to calculate the probability of rock burst and gas outburst occurrences.

The results were summarized in conference papers, one in the proceedings of the 54th US Rock Mechanics/Geomechanics Symposium organized by the American Rock Mechanics Association, 28 June - 1 July 2020 at Golden, Colorado, USA (Link), another in the proceedings of the 55th US Rock Mechanics/Geomechanics Symposium organized by the American Rock Mechanics Association, 18-25 June 2021 at Houston, Texas, USA (Link).

Conclusions and Future Work

Based on the analysis conducted in this research, it can be concluded that the stress-controlled and gas-pressure-controlled mining methods are effective in reducing the liability of rock burst and gas outburst occurrences. The lithological heterogeneity present in the coal seam strongly affects the vertical stress, pore pressure, and gas emission rates, increasing the risk of rock bursts and gas outbursts while mining through the heterogeneous zone. The probabilistic risk assessment framework provides the probability of such occurrences at each excavation step, making it easier for mine management to forecast high-risk situations and adopt suitable control measures. The influence of the change in reservoir properties will be further investigated for their contribution to the occurrence of rock bursts and gas outbursts.